Highlights

An Israeli company aimed to automate their warehouse operations by implementing a robotic mini-load Automated Storage and Retrieval System (ASRS) for efficient goods-to-person order fulfillment.

Primary Objectives

-

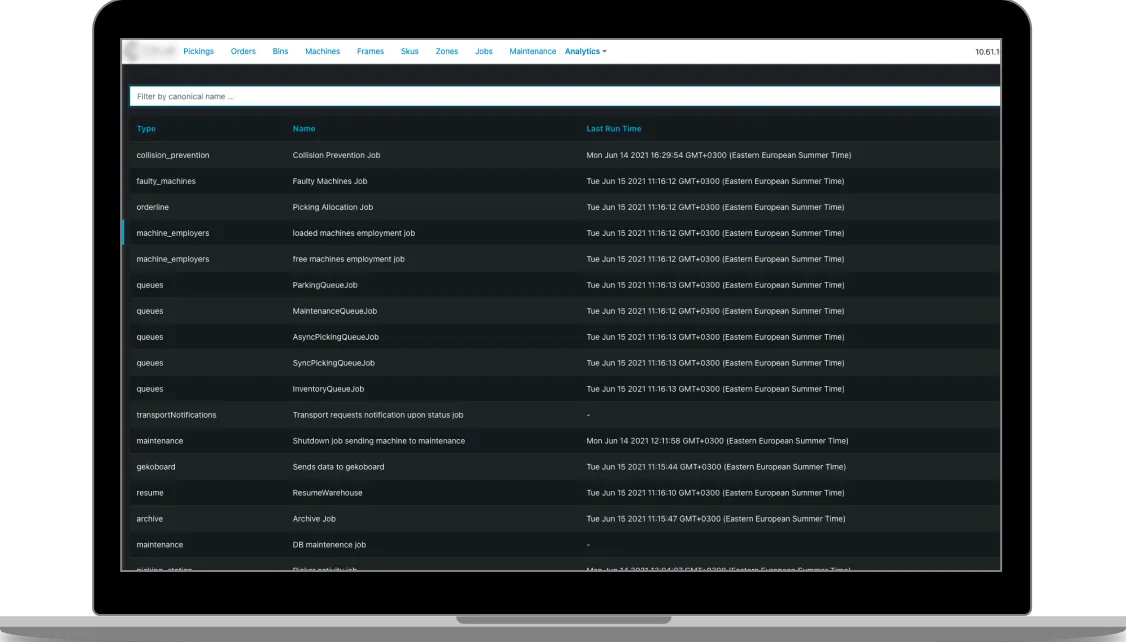

Enhance Order Fulfillment Efficiency:

The project aimed to develop a responsive system that continuously optimizes warehouse operations based on current and predicted orders, increasing throughput and reducing delays.

-

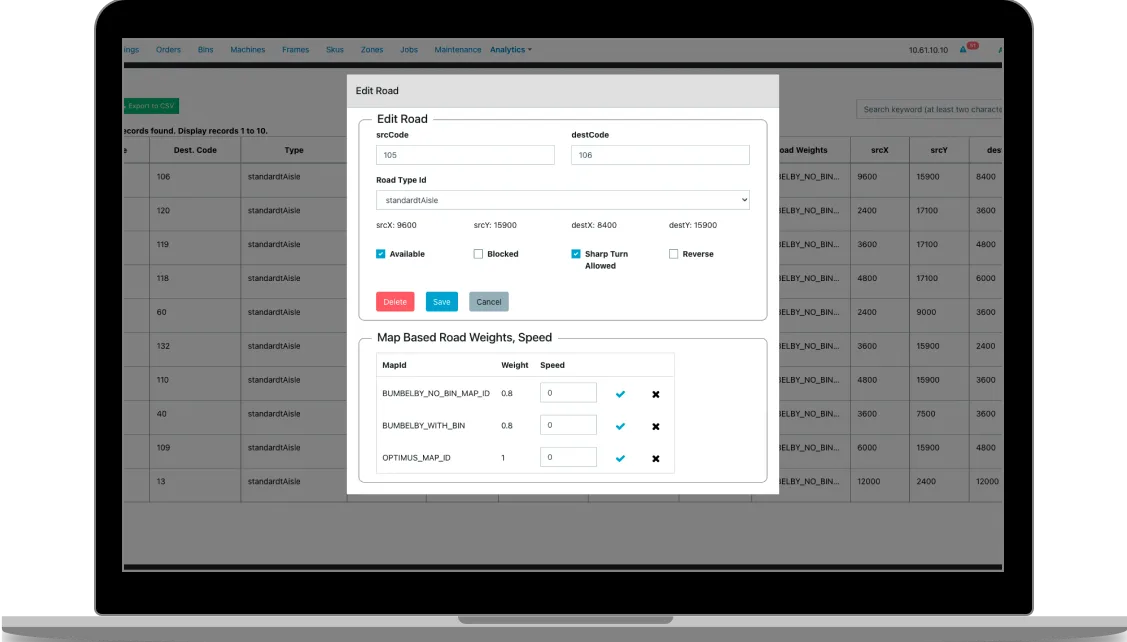

Facilitate Seamless Integration:

A primary objective was to ensure easy integration with existing Warehouse Management Systems (WMS) through well-documented APIs, enabling smooth operations.

-

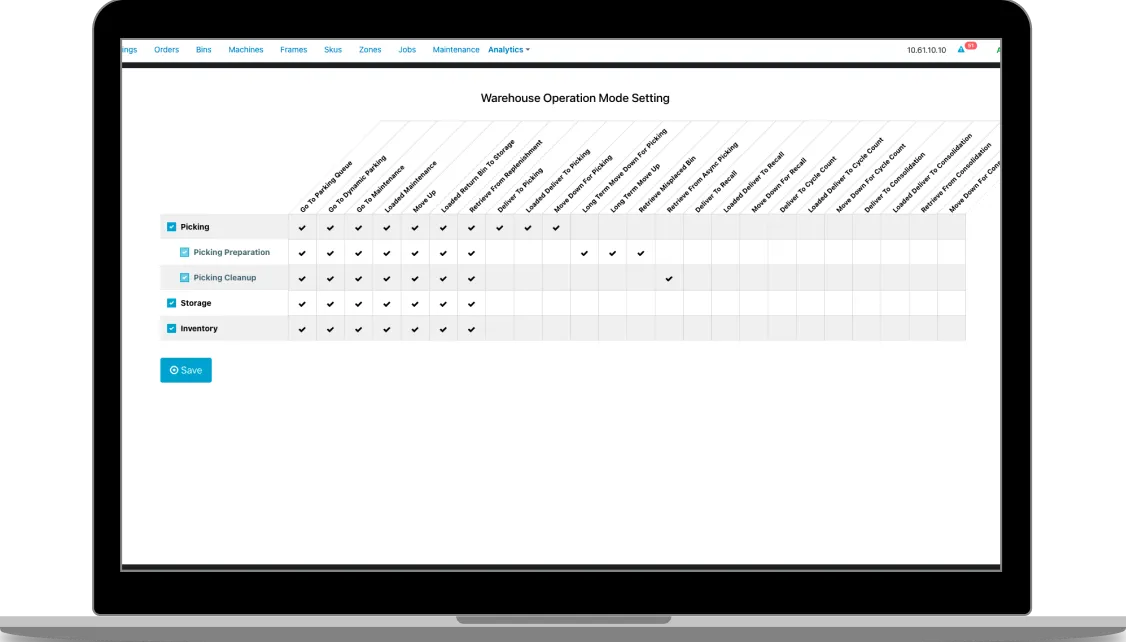

Provide Operational Flexibility:

The system needed to adapt to sudden changes, allowing for quick transitions between robotic and manual picking to respond to unexpected challenges.

How Academy SMART Helped

Business Impact

-

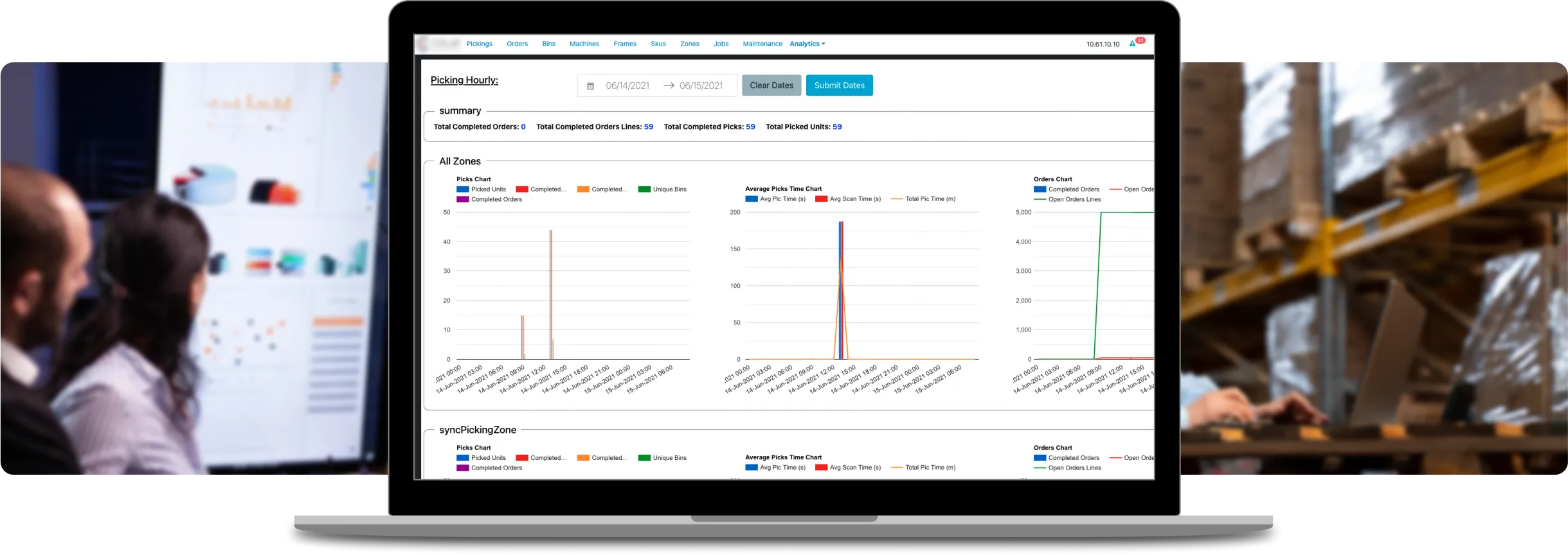

Increased Order Picking Efficiency:

The robotic fulfillment solution significantly enhanced the speed and accuracy of order picking, leading to faster fulfillment times and improved customer satisfaction.

-

Enhanced Warehouse Capacity:

The innovative system optimized storage solutions, allowing the warehouse to handle greater volumes of goods without sacrificing performance.

-

Improved Work Environment:

By automating repetitive tasks, the system reduced manual labor, creating a safer and more efficient work environment for employees.

Summary

Book a free consultation

Reach out to start talking today!